This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Overview

Delivered on time and to budget.

This project is unusual and offered an interesting scope. Delta’s Technical Consultant, Paul Callaghan was approached to give assistance on designing a robust waterproofing solution to a new build basement within a Synagogue in North London. The main contractor having previously worked with Paul, knew Delta would be able to provide this project with a high calibre waterproofing design whilst offering respect for the community it serves.

Synagogues are places for the Jewish community to worship, they are also used as a place to study and often act as a centre for the community.

Synagogues when designed take every aspect of architecture into consideration. Certain synagogues purely through physical means can elicit spiritual inspiration. Some sanctuaries through their sheer magnitude can inspire a feeling of awe; others achieve this effect through opulent materials, beautiful art and carefully designed lighting and sound. Many people report that a synagogue’s architecture helps them feel God’s Presence.

Delta were first approached at the design stage of the project, which allowed Paul to attend the design team meetings, this approach is also embedded in BS 8102:2009.

This project was funded by the Jewish Community it serves. Located within Stanford Hill, a district in the London Borough of Hackney (north-east London).

During on-site attendance it was noted that the hydrostatic head of water pressure in this area was phenomenally high and that the waterproofing design would need to reflect this.

Specification

- NBS Specification J40 (Clause 290) Flexible Sheet Tanking/Damp Proofing

- BS 8102:2009 Type C Drained Protection

Methodology

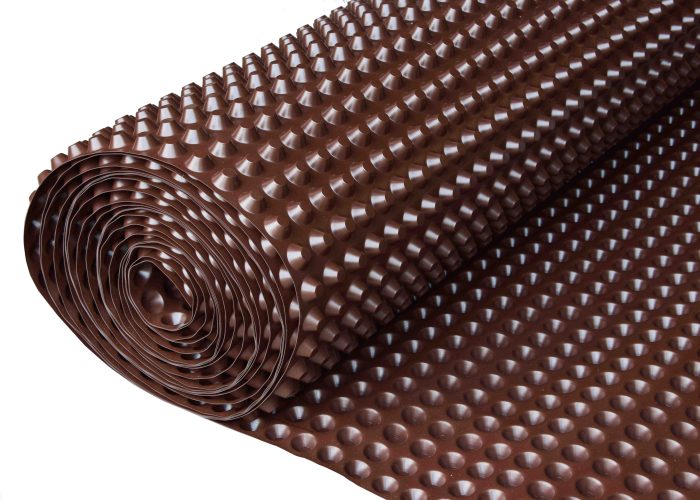

The concept of a drained cavity system is to collect and manage any moisture which breaches the integrity of the structure by channelling, collecting and discharging such free water via a suitable evacuation point such as a Delta packaged pump station.

When specifying a cavity membrane system, full consideration must be given to drainage, when installed below ground. BS 8102:2009 (Code of Practice for Protection of Below Ground Structures Against Water from the Ground) should be incorporated into every waterproofing design.

It should be noted that the waterproofing design for any new build below ground structure should also be carried out by a CSSW (Certified Surveyor in Structural Waterproofing) surveyor so that the client is in full compliance with the latest waterproofing digest 5:4.

Due to the high hydrostatic head of water pressure, there would be ingress issues with the basement if attention to detail was not incorporated from the onset to the waterproofing design working closely with the Geo Technical Engineer and Structural Engineer to design a robust structure for this project. The size of the submersible pump chambers needed to be determined by the volumes of water ingress the Synagogue was likely to experience. The basement was approximately 6 meters deep, being one of the largest in the area.

It’s the moisture you don’t see that is the reason to a sump pump being incorporated into a waterproofing design. Submersible pumps (Sump pumps) offer extra protection to a structure from water ingress.

Paul suggested incorporating into the design the Delta Bespoke Sump Pump range. Delta’s Bespoke Sump Pump range would be able to remove large volumes of ground water in the event of an unexpected defect in the structure, foul and grey waste. Delta’s Sump Pumps are designed and manufactured within the United Kingdom and are capable to withstand hydrostatic forces encountered in all demanding and unsympathetic applications.

Locations of the sump pump units were suggested during the design phase and were installed by the main contractors under the supervision of Delta. By incorporating sump pumps at the design stage, it allowed for project team to work together to create and share a range of project documentation with the benefit of interconnectivity which in turn created better project decisions during the correct stages of the project. Offering the client peace of mind, knowing that if ground water entered the structure the sump pumps were more than capable counteract this issue.

The design was further enhanced by the incorporation of a high-water level alarm which is WIFI enabled offering predictive data to our operation centre monitored 24/7 and a duplex control panel (the powerful Dual V6 pumps were factory set to activate at different levels. One V6 pump being the primary and the secondary pump acting as a back-up).

Synagogue basement being a new build would benefit from an application of Koster Polysil TG 500 (an anti-lime coating/surface primer) which would reduce the risk of excess free lime leaching out of the concrete during the curing process. This free lime, if untreated, can enter the Cavity Drainage System which can impede the flow of water and cause sump pump failure.

Case Study Results

The client confirmed Delta’s expertise and on-site attendance exceeded expectations. The client congratulated Paul on his understanding of expected performance and his ability to explain the reasons for his waterproofing design. Delta were able to review the objectives of the project and present solutions resulting in the Shul and rooms within its basement remaining dry, habitable and fit for purpose.