This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Overview

When it comes to residential, commercial or any structure below ground, waterproofing is a critical component within the construction process for protecting and preserving a building. A poorly designed or installed waterproofing solution can fail leading to significant implications on the structure itself.

Delta Registered Installers, Abtech (UK) Ltd were called upon to give assistance on a particularly technically complicated project where approaches to waterproofing design and installation had been incorporated, however the system had failed. For a great remedial waterproofing outcome, seek assistance from an experienced waterproofing company to inspect your site and carry out the remedial work.

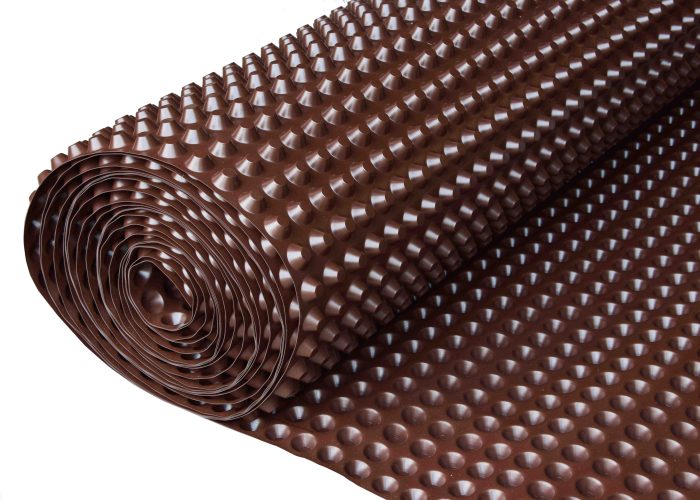

The property when built had a Type C, cavity drain membrane systems incorporated (not a Delta System), however there was no basement drainage incorporated into the design to manage water ingress.

In principle a Type C, drainage system is a water management system. The Type C system is used to control water ingress once it has penetrated the structure. Moisture or running water travel behind the Type C membrane within a controlled drainage system. A Type C System isn’t classified as a barrier but provides protection by means of water management. For a Type System to be successful a suitable drainage system is required to collect and discharge water ingress to a suitable and safe evacuation point (either by natural forces or a mechanical pump system).

When correctly installed, groundwater drainage channels effectively relieve hydrostatic water pressure in the below ground structure. They are installed below flooring membranes at the floor/wall junction.

Methodology

Simon Cane, Abtech’s Waterproofing Manager undertook preliminary site inspections and met with the main contractor to discuss remedial options, methodology for remedial works and cost. During site observations significant water was sitting on the basement slab with perimeter channel rebates filled with rubble. As with any Type C system, any water ingress requires evacuation from the property, there was no points for the evacuation of water ingress exiting this structure.

There was no DPC (damp proof course) on the brickwork allowing rising damp. A damp proof course is one of the most important elements of a property. The DPC protects the property against moisture rising from the ground.

The project was split into two phases.

Phase 1

Temporary works were installed to allow Abtech to remove the blockwork in sections, along with the failed Type C system. Prior to the install of the Delta Cavity Drain System, remedial works were required.

Koster NB1 and Repair Mortar Plus were used to provide new strength to damaged concrete and, offer a permanent repair that is tough enough to stand up to most hydrostatic pressure.

Applied as a closed layer, Koster NB 1 is waterproof to pressurized water up to 13 bar, as they slurry develops an intense bond to the substrate, capillaries are plugged. Besides offering a hydraulic curing of NB 1, crystallizing reactions active within the slurry which can lead to a self-healing effect where micro-cracks develop in concrete.

Rebates within the structural slab were levelled up with all rubble removed.

A DPC was rebuilt in the blockwork with bluebird ties, ensuring the property had an effective damp proof course to repel water from the ground.

Phase 2

Prior to the installation of the Type C system, coved fillets were created at floor/wall junctions. Koster Polysil TG 500 was used to prevent the leaching of free lime in new concrete. Koster Polysil TG 500 if often used in combination with cavity drain membranes and drainage systems.

Delta MS 500 was securely fixed to the internal walls using Delta’s specialist fixing plugs, with Delta MS20 installed to floors.

Below the floor membrane perimeter drainage channels were sited within the rebates allowing for suitable drainage of any future water ingress and this being diverted to suitable discharge point (on this occasion a mechanical pump system).

The need to service and maintain the drainage elements of type C waterproofing systems is paramount to long-term success. Abtech, incorporated inspection ports in the perimeter channel and installed the sump pump in a location that allows easy access for periodic servicing.

After the Type C System was installed the all-important integrity testing was undertaken to exercise the waterproofing system in worst case scenario.

Case Study Results

Abtech (UK) Ltd provided a completely watertight solution following the guidelines set out in BS 8102:2009 (Code of practice for protection of below ground structures against water from the ground) and Approved Documents.

The works were carried out to a high standard and delivered on time, to a tight schedule.

- Technical Drawings