This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Overview

The scope of the project was to facilitate a combined waterproofing solution for a 2,000m² luxurious subterranean space which includes a double-level basement that will accommodate a cinema room, spa and swimming pool wing, changing, and screening rooms, servery, storage & laundry wing, plant rooms and other accommodation.

Delta Registered Installers, Knowles were appointed as principal contractor to collaborate with the architects to fulfill the role of Waterproofing Design Specialists in providing a reliable, watertight solution for this £100m project.

Knowles created combination waterproofing design which was both compliant with British Standard 8102:2009 ‘Code of Practice for Protection of Below Ground Structures Against Water from the Ground’.

Combination waterproofing systems can offer optimal structural protection against water ingress.

Some designers will specify two forms of waterproofing. These specifications “combination” Types A, B & C systems to achieve the desired waterproofing performance and to meet requirements of BS8102:2009. It is always prudent to source these systems, if possible, from a sole source supplier, as this factor will dramatically in reducing risks associated with compatibility of products and assists with technical design issues.

Combination systems are an ideal solution for convoluted/difficult shapes to waterproof and provide continuity of waterproofing design.

In this instance, Knowles suggested a robust solution consisting of Types A, B and C waterproofing for a total risk averse solution.

The project required Grade 3 protection – No dampness or water penetration is acceptable.

Methodology

Delta Registered Installers, Knowles are a leading construction company, specialising in super-prime residential and commercial schemes. Specialists in complex projects, Knowles deliver projects from concept to completion, including shell and core, subterranean, superstructure and fine finishes.

With many new basement projects, the basement is phased and constructed during the start of the build process. Knowles with ease overcome issues encountered during the excavation and tolerances with 30,000m³ of rock and soil being removed to build an open cut basement.

Between the design concept phase and construction, changes were needed to the initial waterproofing design. In limiting the impact of these design changes on project cost and identifying actions required, Delta were on hand. David J. Symes, Delta’s Co-Managing Director attended design meetings and supplied strategies for suitable resolution.

In addition to our Type A and C waterproofing systems, David was delighted to introduce to Knowles our new (Type B) watertight concrete additive, Koster BDM. Koster BDM had previously been used in Europe and extensively in other countries. Koster BDM is a crystallizing integral waterproofing additive for concrete and was supplied for a volume of 3000m³ of waterproof concrete poured over a period of 12 months. The tallest walls were required at 6.750m x 0.5m thick, with the largest spanning slab 10,700m².

Waterproofing concrete offers structures numerous benefits such as strengthening the structure (waterproof concrete lets in less moisture, causing fewer cracks, which means it is less vulnerable to the elements), whilst reducing maintenance costs, all designed to BSEN1992 Euro code 3.

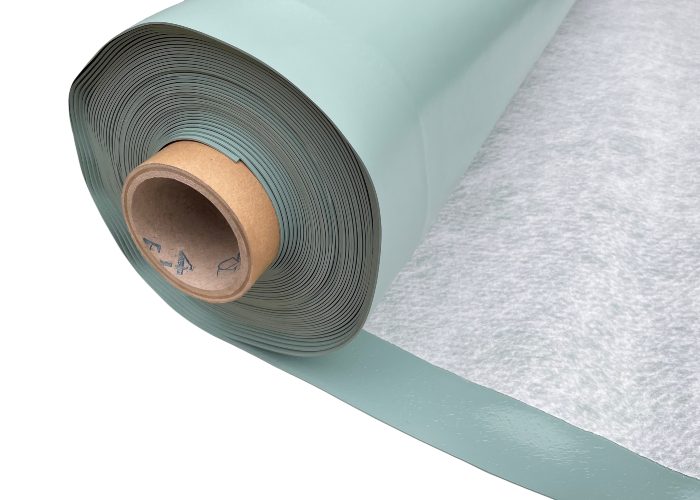

Prior to the pour of the concrete slab, Delta DualProof was utilised. DualProof is a pre-applied, fully, and permanently bonded, composite sheet waterproofing membrane, consisting of a special non-woven Fibre-Tex fleece co-extruded with a highly flexible PVC membrane designed for use with structural reinforced concrete. Freshly poured concrete is embedded completely into the special designed and developed fleece, creating a unique and permanent mechanical bond.

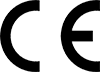

For the vertical waterproofing, Koster Deuxan 2C was expertly spray applied by Knowles. The waterproofing layer was then protected with Delta Geo Drain Quattro, prior to backfilling, which is a combined drainage and protection layer, capable of a loading of 40 metric tonnes.

Delta’s Type C system was used internally, providing negative side waterproofing.

Prior to the installation of the Type C System, all new concrete was treated with Koster Polysil TG 500 to prevent the leaching of free lime, with all construction joints sealed using Koster Repair Mortar Plus. In a full belts and bridges approach, Knowles applied a closed layer of Koster NB 1 sealing slurry to prevent migratory dampness.

All construction joints where sealed using Koster Quellband, hydrophilic waterbar.

Delta’s MS 500 membrane was applied to all vertical earth retained elevations, linked between intermediate level slabs via a concrete bund incorporating Delta drainage channels which was piped from upper to lower level via vertical pipes, with the all-important inspection ports added at approx. 8Lm intervals to ensure that the drainage aspects are fully maintainable and in accordance with BS 8102:2009.

Delta MS 20 membrane, which has a 20mm studded profile for greater drainage capacity, was used across the lower basement ground bearing slab, with the Delta perimeter channel incorporated to provide a suitable drainage solution which led to Delta bespoke sump pumps.

Delta provided a range of bespoke sump chambers to complement the internal Type C Waterproofing solution, all with our latest WIFI enabled high water level alarm which offers predictive maintenance and battery back-up systems to provide 24/7 remote monitoring, acting as a virtual engineer on site, reducing the requirement to conduct unnecessary servicing and reducing the structures carbon footprint.

Case Study Results

Delta’s site services team delivering an exceptional quality assurance and training service throughout.

Knowles have provided a complete bespoke watertight solution following the guidelines set out in BS 8102:2009, with all works undertaken to a high standard and delivered on time, despite changes to the waterproofing design.

Delta is privileged to have been involved in this phenomenal project, in the words of David J. Symes “In my opinion a serious feat of engineering.”